Plastic injection moulding is most likely the most favored producing units for producing plastic pieces and parts at scale. Recognized for its precision, performance, and versatility, injection moulding can be utilized across different industries—from automotive and electronics to buyer goods and health-related units.

What exactly is Plastic Injection Moulding?

Plastic injection moulding involves injecting molten plastic into a pre-built steel mould less than questionable. The plastic cools and solidifies with the mould, using the product of a remaining merchandise. Once the element is fully cooled, It really is ejected inside the mould combined with the cycle begins yet again. This process may be very repeatable, rendering it ideal for mass creation.

Essential Advantages

Just one within the big benefits of plastic injection moulding is its functionality to make sophisticated designs with good precision and consistency. It’s also hugely cost-powerful for top-volume operates, as the same mould could possibly be utilized to produce countless numbers—or perhaps millions—of equivalent sections with small content waste.

Also, a wide array of plastics operates exceptionally effectively during the Procedure, such as engineering-grade polymers like ABS, Nylon, Polycarbonate, and Polypropylene. These resources give various attributes like versatility, sturdiness, chemical resistance, and thermal stability, with regard on here the application.

Applications Across Industries

Plastic injection moulding is utilized in almost every single business. In automotive production, it can help make dashboards, clips, and housings. In healthcare, it’s utilized to produce health care-grade syringes, containers, and unit casings. Electronics producers rely on it for generating sturdy plastic enclosures, buttons, and connectors.

Tooling and Mould Design and style

The quality of the ultimate product or service depends closely throughout the style and design With all the mould. Toolmakers use CAD software program to layout precision moulds, which may be made from hardened steel or aluminium. While the First tariff of mould development might be substantial, the lengthy-phrase generation effectiveness causes it being an highly recommended expenditure for large-scale projects.

Sustainability and Recycling

Contemporary plastic injection moulding amenities are also adopting far more sustainable methods. Leftover plastic material is often reground and reused. Providers like Australian Consolidated Plastics even offer plastic recycling products and services for components like Acrylic and Polycarbonate, promoting a round economic climate in production.

Conclusion

Plastic injection moulding continues to be a cornerstone of contemporary manufacturing. Its efficiency, flexibility, and power to supply regular excellent help it become probably the most perfectly-preferred selection for companies needing reputable, superior-quantity plastic production. As supplies and systems evolve, the activity is continually be somewhat more sustainable and sophisticated—Assembly the pressure of industries around the world.

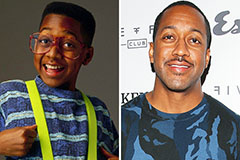

Jaleel White Then & Now!

Jaleel White Then & Now! Alisan Porter Then & Now!

Alisan Porter Then & Now! Burke Ramsey Then & Now!

Burke Ramsey Then & Now! Barbara Eden Then & Now!

Barbara Eden Then & Now! Megyn Kelly Then & Now!

Megyn Kelly Then & Now!